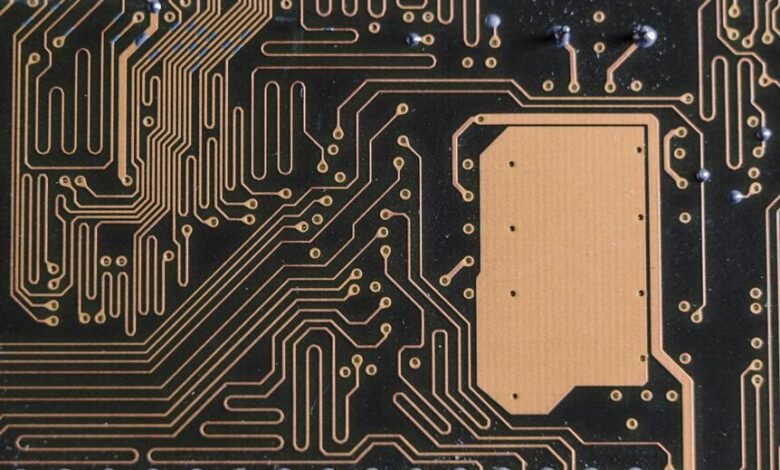

Understanding Pcb Assembly Price Trends in Consumer Electronics Companies

The landscape of PCB assembly pricing in consumer electronics is shaped by a myriad of factors, including market demand, production efficiencies, and technological advancements. As companies navigate these complexities, understanding the nuances of pricing trends becomes essential for strategic decision-making. Notably, fluctuations in demand can create unpredictable pricing scenarios, while supply chain disruptions further complicate cost assessments. As we explore the intricate interplay of these elements, it becomes clear that there are underlying strategies that successful companies employ to adapt and thrive. What are these strategies, and how can they inform future practices?

Overview of PCB Assembly Pricing

The landscape of PCB assembly pricing in consumer electronics is influenced by a myriad of factors, including material costs, labor expenses, and technological advancements. A comprehensive market analysis reveals that pricing models vary significantly across different manufacturers, reflecting diverse strategies to meet customer expectations.

For example, some companies adopt a low-cost model to capture market share, while others prioritize quality and innovation, leading to higher pricing tiers.

Competitor comparison is pivotal, as firms must understand how their prices stack against others in the industry. This awareness drives strategic adjustments to remain competitive.

Regional variations also play a crucial role in pricing; for instance, labor costs in Asia may offer a stark contrast to those in North America or Europe, impacting overall assembly expenses.

Moreover, volume effects cannot be underestimated. Bulk orders often lead to reduced per-unit costs, incentivizing customers to increase order quantities.

As consumer electronics evolve, understanding these multifaceted components will be essential for stakeholders aiming to navigate the complexities of PCB assembly pricing effectively.

Thus, a data-driven approach is vital for aligning business strategies with market realities.

Key Factors Influencing Prices

Several key factors significantly influence PCB assembly prices in the consumer electronics sector. Understanding these variables is essential for companies aiming to optimize costs and enhance profitability.

| Factor | Description | Impact on Price |

|---|---|---|

| Market Demand | Higher demand can drive prices up, while lower demand may reduce them. | Fluctuates prices based on consumer interest. |

| Production Volume | Increased production typically lowers per-unit costs due to economies of scale. | Large orders decrease overall expenses. |

| Material Quality | Higher quality materials often incur higher costs, impacting final pricing. | Essential for product reliability and performance. |

| Labor Costs | Regional labor costs vary greatly, influencing overall assembly expenses. | Affects competitiveness in global markets. |

| Design Complexity | More complex designs require advanced techniques and tools, raising costs. | Complexity often correlates with innovation. |

| Geographical Location | Proximity to suppliers and markets can affect shipping and operational costs. | Impacts logistics and turnaround time. |

Impact of Supply Chain Disruptions

While supply chain disruptions can arise from various sources, including natural disasters, geopolitical tensions, and global pandemics, their impact on PCB assembly prices in consumer electronics is profound.

These disruptions often lead to significant component shortages, which in turn exacerbate manufacturing delays and create logistics challenges. As companies struggle to procure necessary materials, price volatility becomes a critical concern, ultimately affecting the end consumer.

The ramifications of such supply chain issues are multifaceted:

- Component shortages: Increased demand and limited availability drive prices higher.

- Manufacturing delays: Prolonged lead times hinder production schedules, resulting in lost revenue opportunities.

- Logistics challenges: Transportation disruptions increase costs and lead to further delays in product delivery.

- Market fluctuations: Consumer demand can shift rapidly, requiring a responsive supply chain to maintain competitive pricing.

Understanding these dynamics is essential for stakeholders in the consumer electronics sector.

Technological Advancements and Costs

Technological advancements are reshaping the landscape of PCB assembly costs in consumer electronics, influencing both pricing structures and manufacturing efficiencies. Automation benefits have emerged as key drivers, enabling companies to reduce labor costs while increasing production scalability.

As automated processes become more prevalent, the need for manual labor diminishes, altering labor dynamics within the industry.

Moreover, material innovations play a crucial role in enhancing design efficiencies. New materials not only improve the performance of PCBs but also streamline the manufacturing process, ultimately leading to cost reductions.

These innovations are essential for companies to maintain competitiveness in a rapidly evolving market, where quality standards are consistently rising.

Environmental considerations are also gaining prominence, as consumer electronics firms increasingly seek sustainable practices. Investing in eco-friendly materials and processes can initially raise costs; however, the long-term benefits often outweigh these investments, aligning with growing consumer preferences for sustainability.

Ultimately, market competition drives the need for continuous improvement in PCB assembly. Companies that leverage technological advancements to optimize costs while maintaining quality standards will likely position themselves favorably in the market.

The interplay of these factors underscores the importance of embracing innovation in the pursuit of cost-effective PCB assembly solutions.

Strategies for Cost Management

Effective cost management is essential for companies in the consumer electronics sector looking to maintain profitability in the face of fluctuating PCB assembly prices. Implementing strategic initiatives can significantly mitigate costs while ensuring product quality.

Key strategies include:

- Bulk Purchasing: Leveraging economies of scale by purchasing materials in large quantities can reduce unit costs, allowing companies to negotiate better pricing with suppliers.

- Process Optimization: Streamlining production processes through automation and efficient workflow can reduce labor costs and enhance productivity.

- Vendor Negotiation: Establishing strong relationships with suppliers and regularly negotiating terms can lead to cost savings and improved service levels.

- Design Simplification: Creating more straightforward designs can decrease material usage and assembly time, ultimately lowering production costs.

Additionally, maintaining rigorous quality control and effective production scheduling are critical. By minimizing defects and delays, companies can protect their margins and ensure timely delivery.

Collectively, these strategies not only enhance competitiveness but also provide a framework for navigating the complexities associated with PCB assembly pricing in the consumer electronics landscape.

Conclusion

In the intricate landscape of PCB assembly pricing, fluctuations symbolize the ever-changing tides of consumer electronics. By navigating the currents of supply chain disruptions, embracing technological advancements, and implementing strategic cost management, companies can optimize their positions in this competitive arena. Ultimately, understanding these price trends is akin to deciphering a complex map, guiding firms toward sustainable practices that harmonize quality with affordability, ensuring resilience amidst the chaos of market dynamics.